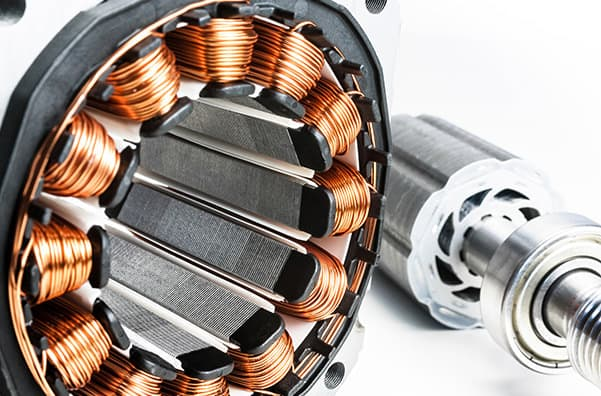

In the world of precision engineering and automation, Brushless DC (BLDC) motors have become the gold standard for reliability and performance. As a leading manufacturer at Flourishing, we often encounter questions about what makes these motors tick—specifically regarding bldc motor efficiency. Why do they outperform their brushed counterparts, and more importantly, how can engineers verify these performance metrics?

This comprehensive guide delves into the science behind efficiency ratings, the testing methodologies used in our labs, and practical tips for optimizing your motor systems.

What is Brushless DC Motor Efficiency?

At its core, efficiency is a ratio. It represents the percentage of total electrical energy input that is successfully converted into useful mechanical energy output. In any electromechanical system, energy that isn't converted into motion is wasted, primarily as heat.

The efficiency of brushless dc motor technology is remarkably high, typically ranging between 85% to 90%. This means that up to 90% of the electrical power fed into the motor drives the load, with only 10% lost to thermal dissipation. By comparison, traditional brushed motors often struggle to surpass 75-80% efficiency due to friction and electrical resistance in the brushes.

For applications where power density and thermal management are critical—such as in our coreless dc motor product line—achieving these high efficiency benchmarks is essential.

How is BLDC Motor Efficiency Tested?

Testing brushless dc motor efficiency requires a controlled environment where inputs and outputs can be measured simultaneously. The fundamental formula involves measuring electrical power (Input) against mechanical power (Output).

How do you test the efficiency of a brushless motor?

To obtain a precise rating, you must account for various "losses"—energy that escapes the system. While a simple input/output calculation gives a rough estimate, a scientific approach involves quantifying specific loss categories:

Copper Loss (I²R Loss)

This is the energy lost as heat due to the electrical resistance of the copper windings. As current flows through the wire, resistance generates heat. The higher the current load, the exponentially higher the copper loss. This is a primary factor in the overall efficiency of bldc motor designs, particularly under heavy loads.

Eddy Current Loss

As the rotor's permanent magnets spin, they induce circulating currents within the stator's iron core. These "eddy currents" generate their own magnetic fields that oppose the motor's rotation, creating drag and heat. Advanced stator lamination techniques are used to minimize this effect.

Hysteresis Loss

Similar to eddy currents, hysteresis loss occurs as the magnetic domains within the stator core are continuously magnetized and demagnetized by the passing rotor. The energy required to constantly flip these magnetic poles manifests as heat.

Friction Loss

Even though BLDC motors lack brushes, they still have bearings. The mechanical friction within the ball bearings creates a drag force that reduces output torque. High-quality bearings are essential to keep this loss negligible.

Viscous Loss

This is the aerodynamic drag (windage) on the rotor spinning through the air, or the fluid drag if the motor contains cooling oil. At very high RPMs, viscous loss becomes a significant factor affecting brushless motor efficiency.

Inverter Loss

BLDC motors require an electronic controller (inverter) to commutate the phases. The switching components (MOSFETs or IGBTs) within the controller have their own internal resistance and switching losses, which must be factored into the total system efficiency.

Brushless Motor Efficiency Equations & Calculation

To calculate efficiency practically, you need to measure Voltage (V), Current (I), Speed (RPM), and Torque (τ). The equation is straightforward:

Motor Efficiency (η) = Mechanical Power Output (Pout) / Electrical Power Input (Pin)

Where:

Pout (Watts) = (Torque in Nm × RPM) × (2π / 60)

Pin (Watts) = Voltage (V) × Current (A)

Testing involves using a dynamometer to apply a known load (torque) while measuring the speed and current draw. By plotting these points across the motor's operating range, engineers generate an efficiency map.

Brushless Motor Efficiency Curve

Efficiency is not a static number; it changes with load and speed. An efficiency curve typically shows a bell shape. The motor is most efficient at a specific combination of high speed and moderate torque. At low speeds or stall conditions, efficiency drops to zero because power is consumed (generating heat) without producing motion.

Understanding this curve helps in selecting the right motor. For example, if you are sourcing a hollow cup motor supplier for a beauty instrument, you want a motor whose peak efficiency point aligns with the device's operating speed to maximize battery life.

Conclusion

Maximizing brushless motor efficiency is a blend of high-quality materials, precision manufacturing, and smart electronic control. By understanding where losses occur—from copper resistance to aerodynamic drag—engineers can fine-tune their designs for optimal performance.

At Flourishing, we leverage 20 years of expertise to produce motors that push the boundaries of what's possible. Whether you need standard BLDC units or custom coreless solutions, our testing protocols ensure you receive the most efficient power delivery for your application. We invite you to contact us to discuss how our high-efficiency motors can elevate your next project.