27mm 3.7V 6V 12V 24V DC 370 pump applied in semiconductors, healthcare, and food processing

The 27mm 370 DC pump (3.7V-24V) is a cornerstone in precision fluid management across semiconductors, healthcare, and food processing. In semiconductor manufacturing, its precise flow control and chemical-resistant materials are vital for handling high-purity solvents and etchants in wafer cleaning and cooling systems. The same precision and reliability make it suitable for diagnostic equipment and analytical instruments in the healthcare sector.

Our research and development focuses on enhancing the pump's diaphragm technology and motor efficiency, allowing for customizable OEM/ODM solutions tailored to specific client needs, such as strict food-grade compliance. This technical expertise is backed by strong production capacity, with a monthly supply capacity of over 100,000 units and a dynamic inventory system ensuring rapid delivery and robust stock availability for global partners.

Product Introduction

This compact 27mm DC 370 pump, operable at 3.7V to 24V, delivers precise and reliable fluid handling for demanding applications. Its robust design ensures consistent performance in semiconductor manufacturing, medical devices, and food processing equipment, making it an ideal component for critical systems.

Specification

Model | Rated voltage | Rated | ||||

Flow | Current | Pressure | Noise | Lifetime | ||

V DC | L/min | mA | kPa | dB | Hours | |

FM370-001V | 3.7 | >3 | <700 | >-60 | <65(at 30cm) | >100 |

| FM370-002V | 6.0 | >3 | <500 | >-60 | <65(at 30cm) | >100 |

| FM370-003V | 12.0 | >3 | <300 | >-60 | <65(at 30cm) | >100 |

Application

1. Semiconductor Manufacturing - Precision chemical transfer.

2. Medical Devices - Fluid control in diagnostics.

3. Food Processing - Sanitary liquid dispensing.

4. Lab Automation - Accurate sample handling.

5. Industrial Cooling - Coolant circulation systems.

6. Water Treatment - Chemical dosing applications.

Details

Customization

We understand the technical and manufacturing challenges motors present and enjoy providing solutions. Through our design we reduce costs and engineering risk, leading to innovative solutions delivered on time and to spec.

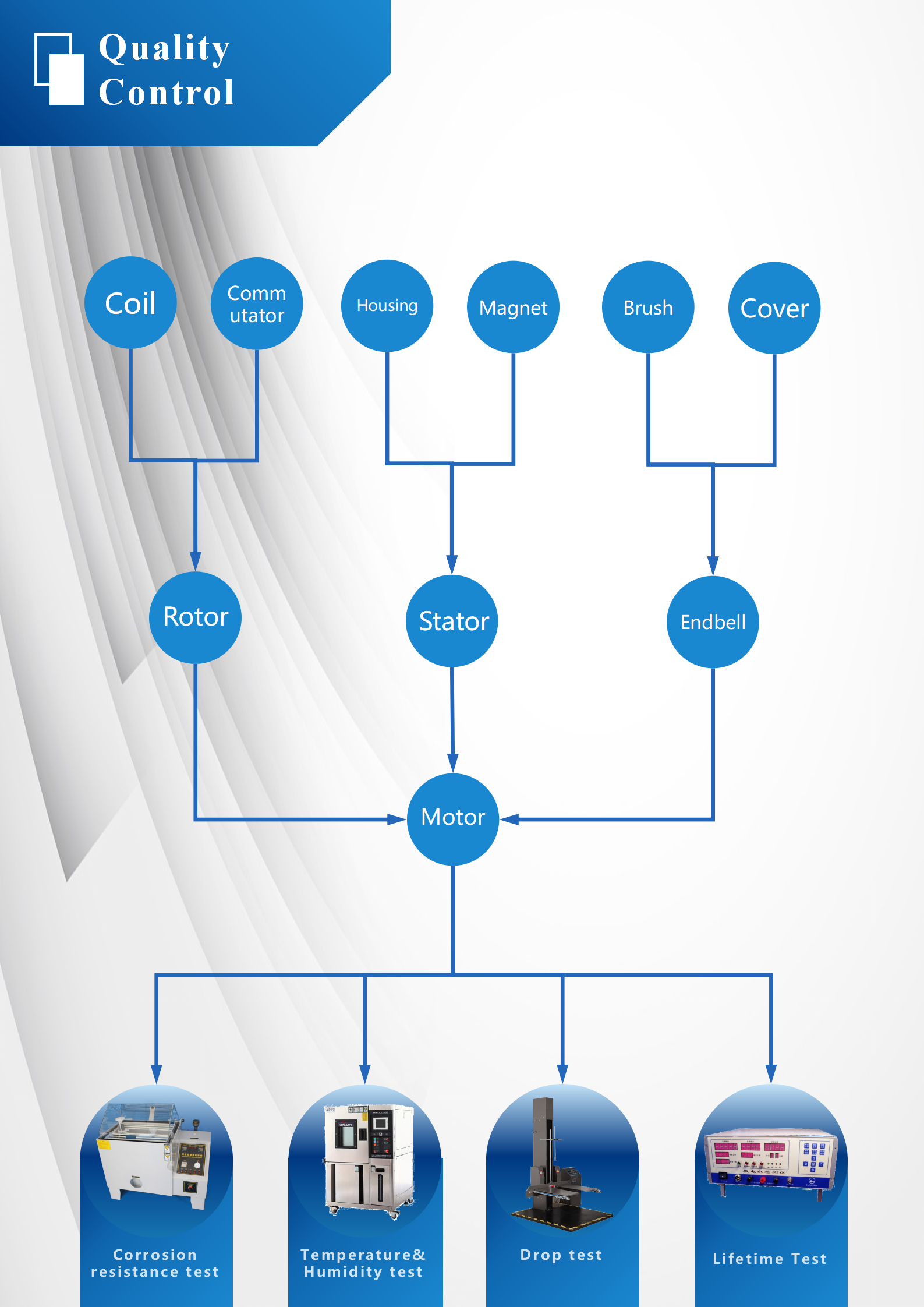

Quality Control

Before leaving the factory, the motor needs to go through a series of tests, including: appearance test, size test, performance test, mechanical test, salt spray test, temperature storage test, drop test, noise test.

Qualification

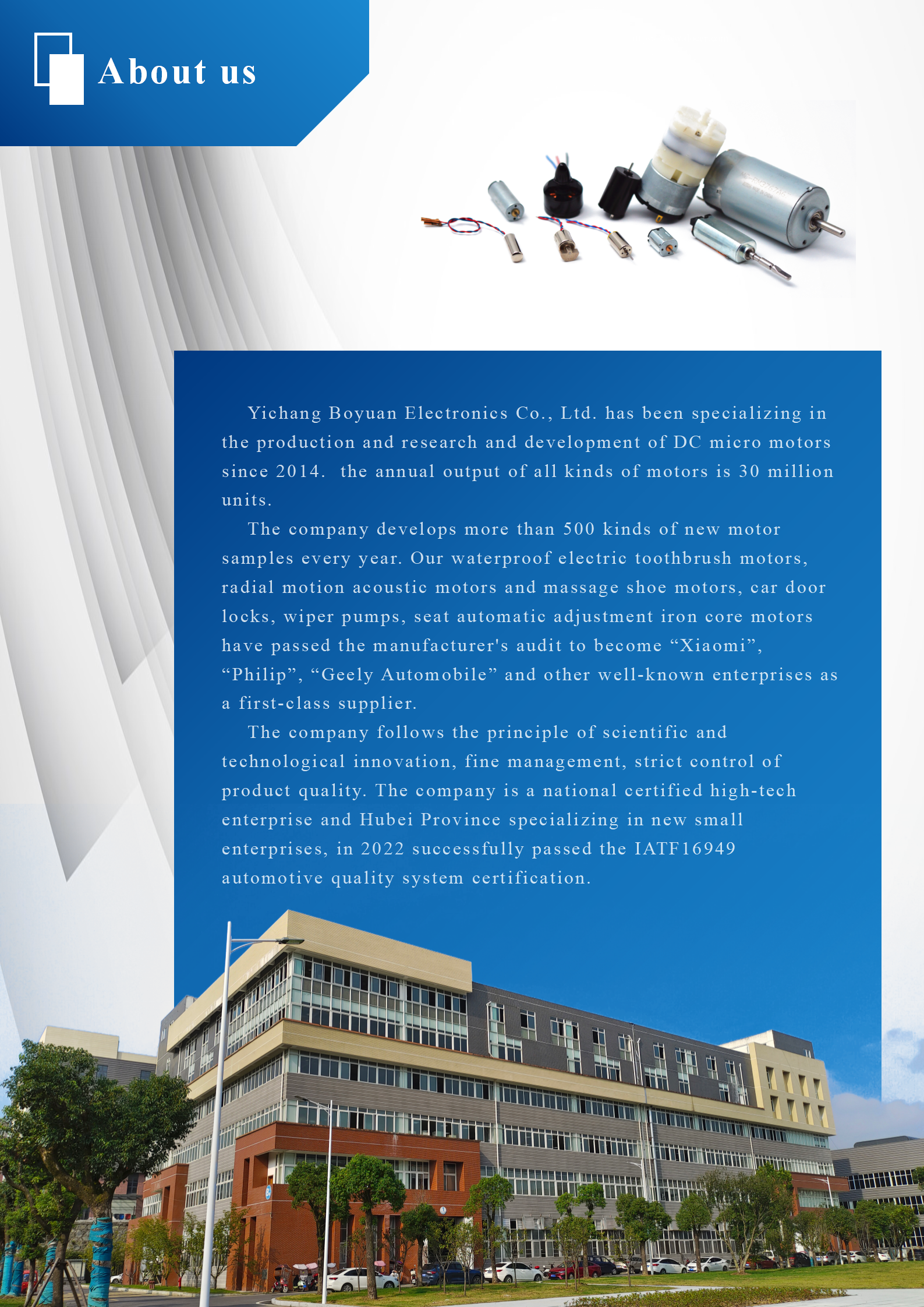

Yichang Flourishing Import & Export Trade Co., Ltd.has been specializing in the production and research and development of DC micro motors since 2014. the annual output of all kinds of motors is 30 million units.

The company develops more than 500 kinds of new motor samples every year. Our waterproof electric toothbrush motors, radial motion acoustic motors and massage shoe motors, car door locks, wiper pumps, seat automatic adjustment iron core motors have passed the manufacturer's audit to become “Xiaomi”, “Philip”, “Geely Automobile” and other well-known enterprises as a first-class supplier.

The company follows the principle of scientific and technological innovation, fine management, strict control of product quality. The company is a national certified high-tech enterprise and Hubei Province specializing in new small enterprises, in 2022 successfully passed the IATF16949 automotive quality system certification.

We have more than ten relevant patents, a core team of 20 people, more than 200 employees, standardized dust-proof workshop of 4,000 square feet, an independent motor laboratory and automated production equipment, the degree of automation in the production of micro-motor components reaches more than 56%, with an annual output of 30 million units of various types of motors.

Our Partnership

At present, the company has become ‘Xiaomi’, ‘Philip’, ‘Geely Automobile’ and other well-known enterprises of the first-class suppliers.