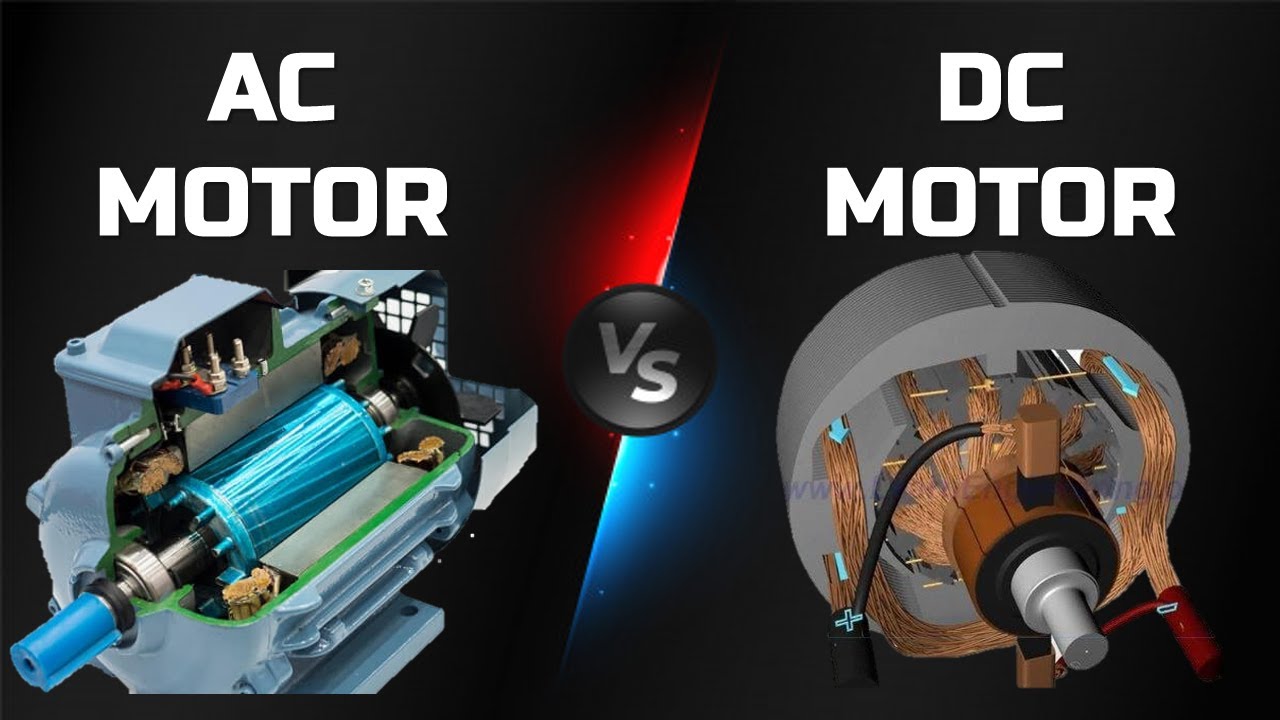

What Is the Difference Between a DC and AC Electric Motor?

What Is the Difference Between a DC and AC Electric Motor?

Electric motors are an integral part of modern life, powering everything from household appliances to industrial machinery. When choosing a motor, one of the most important decisions is whether to use an AC (alternating current) or a DC (direct current) motor. These two types of motors differ significantly in terms of their design, performance, efficiency, and applications. In this article, we’ll explore the differences between AC and DC motors, helping you make an informed decision for your specific needs.

What Do AC and DC Mean?

Before diving into the technical aspects of motors, it’s essential to understand the difference between alternating current (AC) and direct current (DC).

AC refers to the type of electrical current that reverses direction periodically. It is the standard form of electricity supplied to homes and businesses around the world. The voltage in AC systems alternates between positive and negative, which allows for efficient transmission over long distances.

DC refers to the flow of electric charge in a single direction, with a constant voltage level. This is the type of electricity used in batteries and many electronic devices. DC is commonly used in situations where precise control of voltage and current is required.

Motor Design

One of the primary differences between AC and DC motors lies in their design. Both types of motors are made up of two main components: a stator (the stationary part) and a rotor (the rotating part). However, the way these components interact and are powered differs.

AC Motors: The stator of an AC motor produces a rotating magnetic field when an AC current passes through it. This field induces current in the rotor, causing it to turn. The rotor in AC motors can be either a squirrel-cage design or a wound rotor, depending on the specific type of AC motor (such as induction or synchronous).

DC Motors: In a DC motor, the stator provides a constant magnetic field, and the rotor, or armature, has a coil of wire that carries the current. The current is supplied through brushes and a commutator, which reverses the current direction every half-turn. This process keeps the motor rotating in one direction.

The key design difference is that while AC motors rely on a rotating magnetic field induced by an external current, DC motors use direct current to generate a magnetic field that interacts with the rotor, causing it to turn.

Performance

When it comes to performance, AC and DC motors have distinct advantages based on their design.

AC Motors: AC motors generally offer better efficiency at larger scales and for continuous operation. They are well-suited for applications where speed variation is not as critical, such as in industrial machinery, fans, and compressors. AC motors typically perform well under steady load conditions, where the power supply is constant and stable.

DC Motors: DC motors, on the other hand, offer better speed control and torque characteristics. They can be adjusted to different speeds easily, making them ideal for applications requiring variable speed, such as in robotics, electric vehicles, and precise machinery. The ability to fine-tune the speed of DC motors gives them an edge in many applications where dynamic control is necessary.

Efficiency

Efficiency is a crucial factor when choosing between AC and DC motors, especially when considering energy costs over time.

AC Motors: Typically, AC motors are more efficient for large-scale applications, particularly in industries like manufacturing and HVAC systems. They can operate at higher power ratings with relatively low energy consumption. Additionally, AC motors benefit from being able to operate directly from the mains power supply, which reduces the need for additional components such as controllers or converters.

DC Motors: DC motors are highly efficient in small, precise applications. However, they generally suffer from efficiency losses at higher power levels due to the friction of brushes and the wear-and-tear on components like the commutator. Brushless DC motors (BLDC) have been developed to address some of these issues, offering higher efficiency than brushed DC motors by eliminating the need for brushes and reducing friction.

In terms of pure efficiency for high power output, AC motors tend to outperform DC motors, though the latter are more efficient for smaller, low-power applications where precision is essential.

Cost

Cost is often a deciding factor when choosing between AC and DC motors. The manufacturing complexity, materials, and specific applications can influence the price of these motors.

AC Motors: AC motors tend to be less expensive to produce and maintain, especially in large-scale applications. They are more widely used in everyday appliances and industrial equipment, which contributes to lower production costs.

DC Motors: DC motors, particularly brushed ones, tend to be more expensive due to the need for brushes, commutators, and the additional parts required for speed control. Brushless DC motors, although more efficient, are even more costly due to their advanced design and the need for sophisticated controllers.

Overall, AC motors are generally more cost-effective for large-scale applications, while DC motors may have a higher initial cost, but they provide significant advantages in specialized applications requiring precise control.

Reliability and Maintenance

The reliability and maintenance requirements of motors are essential to consider, especially when choosing motors for critical applications or where downtime must be minimized.

AC Motors: AC motors are highly reliable, particularly induction motors, which have no brushes or commutators to wear out. They are known for their durability and low maintenance needs, making them ideal for applications where long-term operation is essential.

DC Motors: DC motors, especially brushed types, require more maintenance due to the wear of brushes and commutators. Over time, the brushes can degrade, leading to the need for regular replacement. Brushless DC motors, however, require far less maintenance and can last longer due to their lack of brushes. However, they still require controllers and other electronic components, which may require occasional maintenance.

Summary

Both AC and DC motors have their unique advantages and applications.

AC Motors are better suited for large-scale applications with constant load requirements, where efficiency and low cost are paramount. They are reliable, durable, and require minimal maintenance.

DC Motors excel in applications where speed control, torque, and precise performance are required. They are more expensive, but their ability to offer adjustable speeds and dynamic control makes them indispensable in applications like robotics, electric vehicles, and small machinery.

When selecting a motor, consider the specific needs of your application, including factors such as efficiency, cost, maintenance, and performance requirements. Understanding the differences between AC and DC motors will help you choose the best motor for your needs and ensure optimal performance for your systems.